Condenser for Marine Boiler Feed System & Steam Turbines

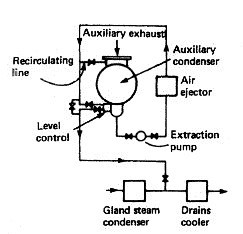

The condenser is a heat exchanger which removes the latent heat from

exhaust steam so that it condenses and can be pumped back into the

boiler. This condensing should be achieved with the minimum of

under-cooling, i.e. reduction of condensate temperature below the

steam temperature. A condenser is also arranged so that gases and

vapours from the condensing steam are removed.

- Flow Measurement

- Four Stroke Engines

- Two Stroke Engines

- Fuel Injection System

- Fuel Oil System

- Lub Oil filters

- MAN B&W Engine

- Sulzer Diesel Engine

- Marine Condensers

- Oily Water Separator

- Overspeed Protection

- Piston & Piston rings

- Crankshaft Deflection

- SewageTreatment Plant

- Starting Air System

- Emergency Power Supply

- UMS Operations

- Drydocking & Repairs

- Critical Machinery

- Deck Machineries

- Control Instrumentation

- Engine Room Safety

- Home