The use of exhaust gases from diesel main propulsion engines to

generate steam is a means of heat energy recovery and improved plant

efficiency.

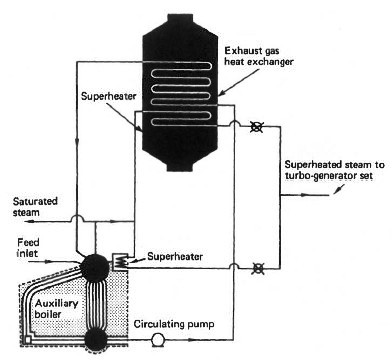

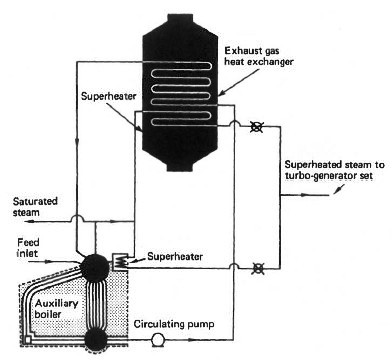

An exhaust gas heat exchanger is shown in Figure above. It is simply a

row of tube banks circulated by feedwater over which the exhaust gases

flow. Individual banks may be arranged to provide feed heating, steam

generation and superheating. A boiler drum is required for steam

generation and separation to take place and use is usually made of the

drum of an auxiliary boiler.

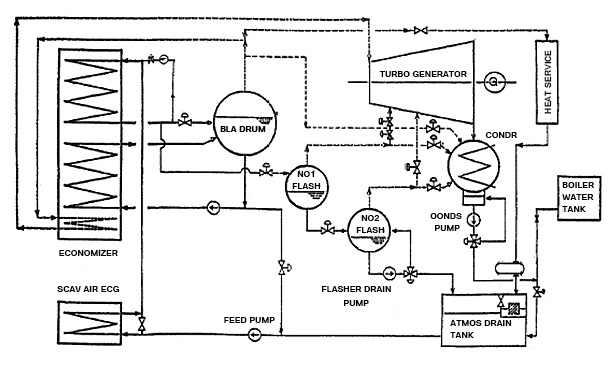

Fig: Auxiliary steam plant system