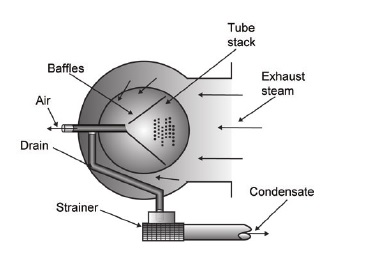

An `End on' or Axial Exhaust Condenser for Marine Feed System

The function of a condenser is to remove latent heat from

exhaust steam so that the condensate obtained can be handled

by pumps in the feed system.

It is also required to reduce the back pressure and so allowing a greater amount of work to be done by the engine, improving efficiency. Sketch right describe an `end on' or axial exhaust regenerative condenser. In this type, steam flowing along the regenerative passage and up into the tube nest heats the condensed droplets from the tubes so there is practically no temperature drop in the condenser. Air trapped by the exhaust baffles is extracted separately by an ejector.

It is also required to reduce the back pressure and so allowing a greater amount of work to be done by the engine, improving efficiency. Sketch right describe an `end on' or axial exhaust regenerative condenser. In this type, steam flowing along the regenerative passage and up into the tube nest heats the condensed droplets from the tubes so there is practically no temperature drop in the condenser. Air trapped by the exhaust baffles is extracted separately by an ejector.