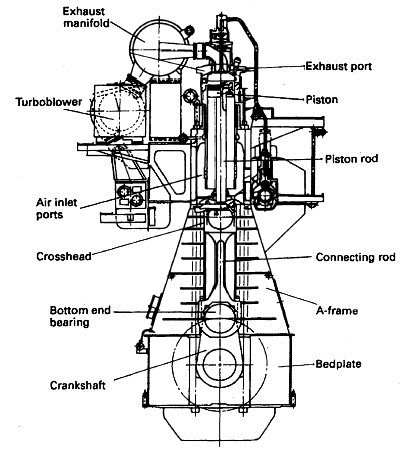

Two-stroke Cycle Marine Diesel Engine

The two-stroke cycle is completed in two strokes of the piston or one

revolution of the crankshaft. In order to operate this cycle where each

event is accomplished in a very short time, the engine requires a number

of special arrangements. First, the fresh air must be forced in under

pressure. The incoming air is used to clean out or scavenge the exhaust gases and then to fill or charge the space with fresh air. Instead of valves

holes, known as 'ports', are used which are opened and closed by the

sides of the piston as it moves.