Steering gear requirement for various ship types

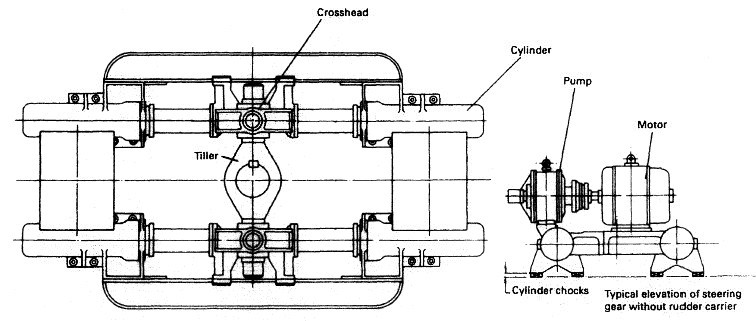

Every ocean going cargo ship need to be provided with a main steering gear and an auxiliary steering

gear unless the main steering gear comprises two or more identical power units.

The main steering gear is to be capable of putting the rudder over

from 35° on one side to 35° on the other side with the ship at its deepest

draft and running ahead at maximum service speed, and under the same

conditions from 35° on either side to 30° on the other side in not more than

28 seconds. It is to be power operated where necessary to meet the above

conditions and where the stock diameter exceeds 120mm.

- Flow Measurement

- Four Stroke Engines

- Two Stroke Engines

- Fuel Injection System

- Fuel Oil System

- Lub Oil filters

- MAN B&W Engine

- Sulzer Diesel Engine

- Marine Condensers

- Oily Water Separator

- Overspeed Protection

- Piston & Piston rings

- Crankshaft Deflection

- SewageTreatment Plant

- Starting Air System

- Emergency Power Supply

- UMS Operations

- Drydocking & Repairs

- Critical Machinery

- Deck Machineries

- Control Instrumentation

- Engine Room Safety

- Home