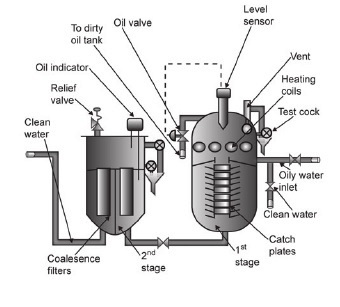

Oily Water Separator for Marine Machinery Installations

Oil/water separators are used to ensure that ships do not discharge oil

when pumping out bilges, oil tanks or any oil-contaminated space.

International legislation relating to oil pollution is becoming more and

more stringent in the limits set for oil discharge.

The oily water separator (OWS) is a very important piece of equipment carried on board. It is used to ensure that water is discharged overboard within legal limits. The OWS must be maintained in full working order and operated according to MARPOL regulations.

The oily water separator (OWS) is a very important piece of equipment carried on board. It is used to ensure that water is discharged overboard within legal limits. The OWS must be maintained in full working order and operated according to MARPOL regulations.