How De-aerator works in a boiler feed system- MachinerySpaces.com

The de-aerator completes the air and vapour removal process begun in

the condenser. It also functions as a feed heater, but in this case operates

by direct contact. The feedwater is heated almost to the point of boiling,

which releases all the dissolved gases which can then be vented off.

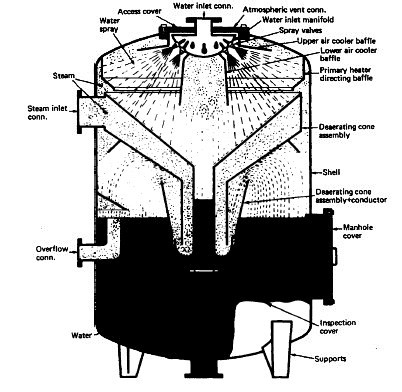

One type of de-aerator is shown in Figure above. The incoming feedwater passes through a number of spray valves or nozzles: the water spray thus provides a large surface area for contact with the heating system. Most of the feedwater will then fall onto the upper surface of the de-aerating cone where it is further heated by the incoming steam. The feedwater then enters the central passage and leaves through a narrow opening which acts as an eductor or ejector to draw steam through with the feed.

One type of de-aerator is shown in Figure above. The incoming feedwater passes through a number of spray valves or nozzles: the water spray thus provides a large surface area for contact with the heating system. Most of the feedwater will then fall onto the upper surface of the de-aerating cone where it is further heated by the incoming steam. The feedwater then enters the central passage and leaves through a narrow opening which acts as an eductor or ejector to draw steam through with the feed.