Displacement, Axial flow and Centrifugal Pumps for Ship Use

A pump is a machine used to raise liquids from a low point to a high

point. Alternatively it may simply provide the liquid with an increase in

energy enabling it to flow or build up a pressure. The pumping action

can be achieved in various ways according to the type of pump

employed. The arrangement of pipework, the liquid to be pumped and

its purpose will result in certain system requirements or characteristics

that must be met by the pump.

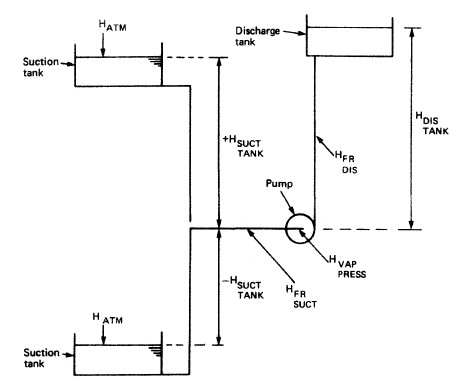

A pumping system on a ship will consist of suction piping, a pump and discharge piping . The system is arranged to provide a positive pressure or head at some point and discharge the liquid. The pump provides the energy to develop the head and overcome any losses in the system. Losses are mainly due to friction within the pipes and the difference between the initial and final liquid levels.

A pumping system on a ship will consist of suction piping, a pump and discharge piping . The system is arranged to provide a positive pressure or head at some point and discharge the liquid. The pump provides the energy to develop the head and overcome any losses in the system. Losses are mainly due to friction within the pipes and the difference between the initial and final liquid levels.