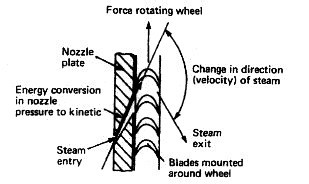

Steam turbines and gearing - operating principle

The shaping of the blades causes a change in direction and hence the velocity of the steam jet. A change in the velocity for a given mass flow of steam produces a force which turns the turbine wheel.The steam turbine has until recently been the first choice for very large power marine propulsion units. Its advantages of little or no vibration, low weight, minimal space requirements and low maintenance costs are considerable.