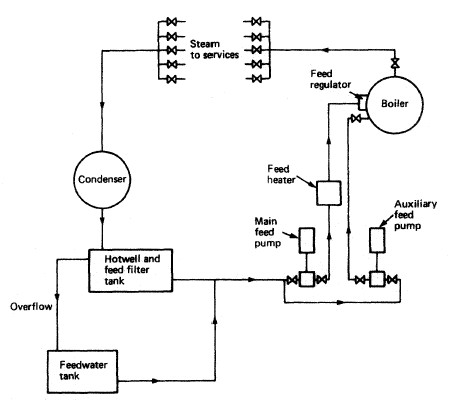

Open Feed System for Marine Auxiliary Boiler

The feed system completes the cycle between boiler and turbine to

enable the exhausted steam to return to the boiler as feedwater. The

feed system is made up of four basic items: the boiler, the turbine, the

condenser and the feed pump. The boiler produces steam which is

supplied to the turbine and finally exhausted as low-energy steam to the

condenser. The condenser condenses the steam to water (condensate)

which is then pumped into the boiler by the feed pump.