Turbochargers safety and procedure for turbocharger cleaning

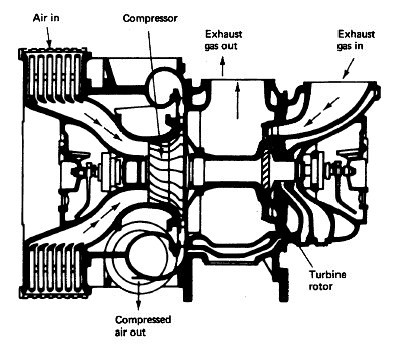

Turbochargers are among the most technologically advanced engine

component onboard ship. Impeller blades of a medium sized turbocharger

regularly rotate at as much as 400 revolutions per second. The outer edges

of the rotor blades thus move at 1.5 times the speed of sound.

Safety

Great care must be exercised in the operation and maintenance of turbochargers. With regard to safety, it is essential to avoid the build up of fuel, cylinder or lubricating oil in the exhaust trunking before the turbocharger as it may result in combustion taking place in the exhaust manifold. Under these conditions the increase in quantity of exhaust gas available to the turbocharger can result in disastrous over speeding.

Safety

Great care must be exercised in the operation and maintenance of turbochargers. With regard to safety, it is essential to avoid the build up of fuel, cylinder or lubricating oil in the exhaust trunking before the turbocharger as it may result in combustion taking place in the exhaust manifold. Under these conditions the increase in quantity of exhaust gas available to the turbocharger can result in disastrous over speeding.