Auxiliary Feed Systems for Marine Boilers and Steam Turbines

How the feed system works for ships machinery?

The feed system completes the cycle between boiler and turbine to

enable the exhausted steam to return to the boiler as feedwater. The arrangements for steam recovery from auxiliaries and ship services

may form separate open or closed feed sysems or be a part of the main

feed system.

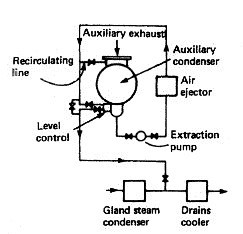

Where, for instance, steam-driven deck auxiliaries are in use, a separate auxiliary condenser operating at about atmospheric pressure will condense the incoming steam . An extraction pump will supply the condensate to an air ejector which will return the feedwater to the main system at a point between the gland steam condenser and the drains cooler.

Where, for instance, steam-driven deck auxiliaries are in use, a separate auxiliary condenser operating at about atmospheric pressure will condense the incoming steam . An extraction pump will supply the condensate to an air ejector which will return the feedwater to the main system at a point between the gland steam condenser and the drains cooler.