Home || Diesel Engines

||Boilers||Feed Systems

||Steam Turbines ||Fuel Treatment ||Pumps ||Refrigeration ||

Ships Propeller Shaft -Thrust block & Shaft bearings

The transmission system on a ship transmits power from the engine to

the propeller. It is made up of shafts, bearings, and Finally the propeller

itself. The thrust from the propeller is transferred to the ship through

the transmission system.

The different items in the system include the thrust shaft, one or more

intermediate shafts and the tailshaft. These shafts are supported by the

thrust block, intermediate bearings and the sterntube bearing. A sealing

arrangement is provided at either end of the tailshaft with the propeller

and cone completing the arrangement. These parts, their location and

purpose are shown in Figure below.

Thrust block

The thrust block transfers the thrust from the propeller to the hull of

the ship. It must therefore be solidly constructed and mounted onto a

rigid seating or framework to perform its task.

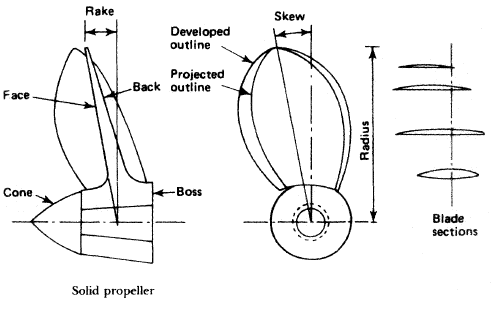

Fig: A solid fixed-pitch propeller

Fig: Thrust block arrangement

The casing of the independent thrust block is in two halves which are

joined by fitted bolts (Figure above). The thrust loading is carried by

bearing pads which are arranged to pivot or tilt. The pads are mounted

in holders or carriers and faced with white metal. In the arrangement

shown the thrust pads extend threequarters of the distance around the

collar and transmit all thrust to the lower half of the casing. Other

designs employ a complete ring of pads.

An oil scraper deflects the oil

lifted by the thrust collar and directs it onto the pad stops. From here it

cascades over the thrust pads and bearings. The thrust shaft is

manufactured with integral flanges for bolting to the engine or gearbox

shaft and the intermediate shafting, and a thrust collar for absorbing the

thrust.

Fig: Propeller shaft arrangement

Shaft bearings

Shaft bearings are of two types, the aftermost tunnel bearing and all

others. The aftermost tunnel bearing has a top and bottom bearing shell

because it must counteract the propeller mass and take a vertical upward

thrust at the forward end of the tailshaft. The other shaft bearings only

support the shaft weight and thus have only lower half bearing shells.

An intermediate tunnel bearing is shown in Figure below.

Fig: Tunnel bearing arrangement

The usual

journal bush is here replaced by pivoting pads. The tilting pad is better

able to carry high overloads and retain a thick oil lubrication film.

Lubrication is from a bath in the lower half of the casing, and an oil

thrower ring dips into the oil and carries it round the shaft as it rotates.

Cooling of the bearing is by water circulating through a tube cooler in

the bottom of the casing.

Related information

- Oil lubricated sterntube bearing, sterntube seals & shafting arrangement

The sterntube bearing serves two important purposes. It supports the tailshaft and a considerable proportion of the propeller weight. It also acts as a gland to prevent the entry of sea water to the machinery space.....

-

Function of solid fixed pitch propeller & Propeller mounting

The propeller consists of a boss with several blades of helicoidal form attached to it. When rotated it 'screws' or thrusts its way through the water by giving momentum to the column of water passing through it. The thrust is transmitted along the shafting to the thrust block and finally to the ship's structure....

- Controllable pitch propeller

A controllable pitch propeller is made up of a boss with separate blades mounted into it. An internal mechanism enables the blades to be moved simultaneously through an arc to change the pitch angle and therefore the pitch....

-

Ships propeller shaft -Thrust block & Shaft bearings

The transmission system on a ship transmits power from the engine to the propeller. It is made up of shafts, bearings, and Finally the propeller itself. The thrust from the propeller is transferred to the ship through the transmission system....

-

Ships steering gear arrangement and testing requirement

The main steering gear is to be capable of putting the rudder over

from 35° on one side to 35° on the other side with the ship at its deepest

draft and running ahead at maximum service speed, and under the same

conditions from 35° on either side to 30° on the other side in not more than

28 seconds.....

-

Ships steering gear electrical control

The electrical remote control system is commonly used in modern installations since it uses a small control unit as transmitter on the bridge

and is simple and reliable in operation.Movement of the bridge transmitter

results in electrical imbalance and current flow to the motor.

.....

-

Ships steering gear telemotor control

Telemotor control is a hydraulic control system employing a transmitter, a receiver, pipes and a charging unit. The transmitter, which is built into

the steering wheel console, is located on the bridge and the receiver is

mounted on the steering gear..

.....

Marine machineries - Useful tags

Marine diesel engines ||Steam generating plant ||Air conditioning system ||Compressed air ||Marine batteries ||Cargo refrigeration ||Centrifugal pump ||Various coolers ||Emergency power supply ||Exhaust gas heat exchangers ||Feed system ||Feed extraction pump ||

Flow measurement || Four stroke engines || Fuel injector || Fuel oil system || Fuel oil treatment ||Gearboxes || Governor ||

Marine incinerator ||

Lub oil filters ||

MAN B&W engine ||

Marine condensers ||

Oily water separator ||

Overspeed protection devices ||

Piston & piston rings ||

Crankshaft deflection ||

Marine pumps ||

Various refrigerants ||

Sewage treatment plant ||

Propellers ||

Power Plants

||

Starting air system ||

Steam turbines ||

Steering gear ||

Sulzer engine ||

Turbine gearing ||

Turbochargers ||

Two stroke engines ||

UMS operations ||

Drydocking & major repairs ||

Critical machinery ||

Deck machineries & cargo gears

|| Control and instrumentation

||Fire protection

||Engine room safety ||

Machinery Spaces.com is about working principles, construction and operation of all the machinery

items in a ship intended primarily for engineers working on board and those who working ashore . For any remarks please

Contact us

Copyright © 2010-2016 Machinery Spaces.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||