Home || Diesel Engines

||Boilers||Feed Systems

||Steam Turbines ||Fuel Treatment ||Pumps ||Refrigeration ||

Enclosed Spaces Entry - machinery space procedures -Safety precautions

The engine room is a place where accidents can easily occur if safe working practices and pollution prevention measures are not strictly followed. The Chief Engineer is responsible for ensuring that the importance of accident/incident prevention is fully understood by all engineering staff including the potential risks involved.

Enclosed Spaces Entry - machinery space procedures

Oxygen deficiency may occur in certain spaces onboard ship

due to rusting which extracts oxygen from the air ,painting without

sufficient ventilation and fuel tanks may also be deficient of oxygen due to hydro

carbons.

Safety precautions need to be taken before entry into an enclosed space are as follows:

- An entry permit must be obtained from a responsible

officer, you may be the issuing officer

-

the space is to be well ventilated and oxygen levels tested

by an O2 meter

-

safety gear, such as self-contained breathing apparatus and

rescue lines must be at hand

-

while anyone is in the enclosed space, someone must be on

standby at the entrance who must be in communication with

the people in the space and must be able to raise the alarm

if they are to get into difficulties.

A permit will be required for entering fuel tanks or other

enclosed spaces onboard.

BA set

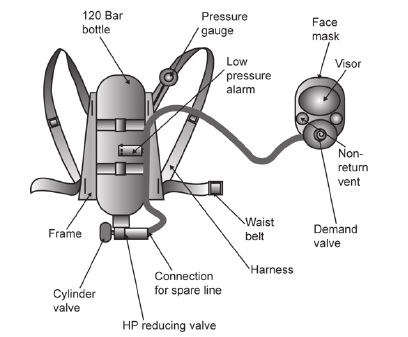

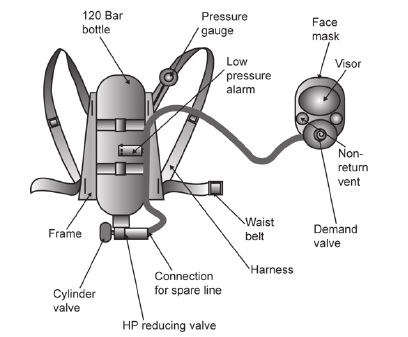

Sketch of a BA set and its use for entry into an enclosed space :

The sketch shows a self-contained breathing apparatus

set, which consists of an air bottle of 120 bar attached

to a frame and harness. The air bottle is attached to a

cylinder stop valve and high pressure reducing valve

which supplies air to the demand valve on the face mask

via a low pressure alarm and pressure gauge. The demand

valve on the face mask can be operated in two modes,

constant pressure or on demand (ie as you breath). The

duration for this type of set is 25 30 minutes, but this

may be greatly reduced depending on the rate of physical

work.

A bottle is checked before use to ensure it is fully charged

and able to give its full duration of use.

Check carried out are:

- Bottle check to ensure it is fully charged and able to

give its full duration of use

- all hoses to ensure they are okay and these are no lakes

- low pressure alarm this will usually operate when

there is 20% left in the bottle, allowing 5 minutes

escape time

- face seal check to ensure a good seal on the face

mask.

As a final point, the Chief Engineer is to employ all available means in order to create a safety entry inside any enclosed spaces of Engine room. Such means include the holding of safety meetings, complying with permit to enter, the viewing of training videos and complying of Company manuals.

Related Information:

Responsibilities of the engineer working in machinery spaces

MAN B&W diesel engine - Basic principles and operational guideline

How a sulzer engine works ? Sulzer RTA72U diesel engine -Operational guideline

Oxygen analyser working principle

Four stroke cycle diesel engines

The fuel oil system for a diesel engine

Function of fuel injector

Lubricating oil system for a marine diesel engine

Fresh water & sea water cooling system

Two stroke cycle diesel engines

Scavenging methods

Dealing scavange fires

Heat exchanger for running machinery

Starting air system for diesel engine

Power measurement -Engine indicator

Sea water circulation of coolers

Gearing arrangement

Function of governors

Couplings, clutches and gearboxes of a marine diesel engine

Explosion relief valve

Cylinder relief valve

Diesel engine Turning gear

Crankcase oil mist detector

Marine machineries - Useful tags

Marine diesel engines ||Steam generating plant ||Air conditioning system ||Compressed air ||Marine batteries ||Cargo refrigeration ||Centrifugal pump ||Various coolers ||Emergency power supply ||Exhaust gas heat exchangers ||Feed system ||Feed extraction pump ||

Flow measurement || Four stroke engines || Fuel injector || Fuel oil system || Fuel oil treatment ||Gearboxes || Governor ||

Marine incinerator ||

Lub oil filters ||

MAN B&W engine ||

Marine condensers ||

Oily water separator ||

Overspeed protection devices ||

Piston & piston rings ||

Crankshaft deflection ||

Marine pumps ||

Various refrigerants ||

Sewage treatment plant ||

Propellers ||

Power Plants

||

Starting air system ||

Steam turbines ||

Steering gear ||

Sulzer engine ||

Turbine gearing ||

Turbochargers ||

Two stroke engines ||

UMS operations ||

Drydocking & major repairs ||

Critical machinery ||

Deck machineries & cargo gears

|| Control and instrumentation

||Fire protection

||Engine room safety ||

Machinery Spaces.com is about working principles, construction and operation of all the machinery

items in a ship intended primarily for engineers working on board and those who working ashore . For any remarks please

Contact us

Copyright © 2010-2016 Machinery Spaces.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||