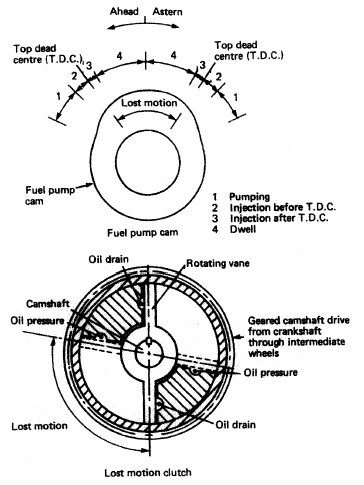

Reversing gears of a marine diesel engine

The diesel engine is a type of internal combustion engine which ignites

the fuel by injecting it into hot, high-pressure air in a combustion

chamber. In common with all internal combustion engines the diesel

engine operates with a fixed sequence of events, which may be achieved

either in four strokes or two, a stroke being the travel of the piston

between its extreme points. Each stroke is accomplished in half a

revolution of the crankshaft.