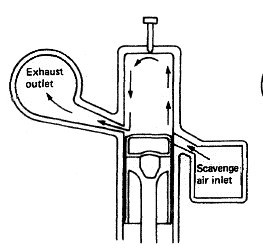

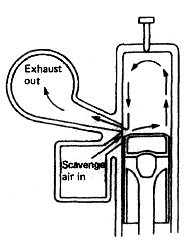

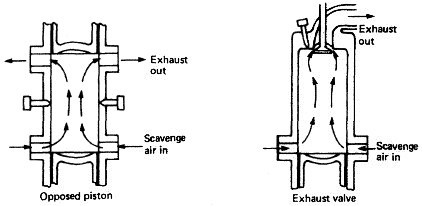

Scavenging methods - Cross-flow scavenging, loop scavenging, & uniflow scavenging

Internal combustion engine procedure:

A basic part of the cycle of an internal combustion engine is the supply

of fresh air and removal of exhaust gases. This is the gas exchange

process. Scavenging is the removal of exhaust gases by blowing in fresh

air. Charging is the filling of the engine cylinder with a supply or charge

of fresh air ready for compression. With supercharging a large mass of air

is supplied to the cylinder by blowing it in under pressure.

Efficient scavenging is essential to ensure a sufficient supply of fresh air for combustion. In the four-stroke cycle engine there is an adequate overlap between the air inlet valve opening and the exhaust valve closing. With two-stroke cycle engines this overlap is limited and some slight mixing of exhaust gases and incoming air does occur.

Efficient scavenging is essential to ensure a sufficient supply of fresh air for combustion. In the four-stroke cycle engine there is an adequate overlap between the air inlet valve opening and the exhaust valve closing. With two-stroke cycle engines this overlap is limited and some slight mixing of exhaust gases and incoming air does occur.

- Flow Measurement

- Four Stroke Engines

- Two Stroke Engines

- Fuel Injection System

- Fuel Oil System

- Lub Oil filters

- MAN B&W Engine

- Sulzer Diesel Engine

- Marine Condensers

- Oily Water Separator

- Overspeed Protection

- Piston & Piston rings

- Crankshaft Deflection

- SewageTreatment Plant

- Starting Air System

- Emergency Power Supply

- UMS Operations

- Drydocking & Repairs

- Critical Machinery

- Deck Machineries

- Control Instrumentation

- Engine Room Safety

- Home