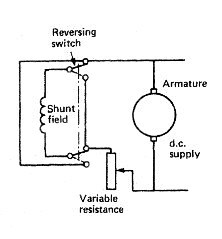

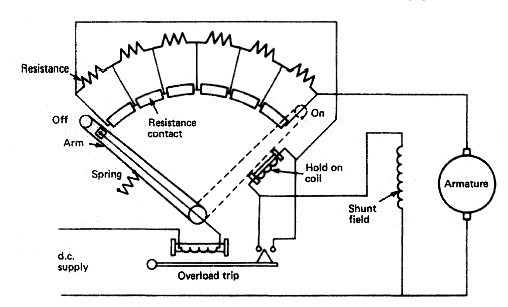

Shunt Wound d.c. Motor, Series Wound d.c. Motor & d.c. Motor Starter

When a current is supplied to a single coil of wire in a magnetic field a

force is created which rotates the coil. This is a similar situation to the

generation of current by a coil moving in a magnetic field. In fact

generators and motors are almost interchangeable, depending upon

which two of magnetic field, current and motion are provided.