Electrical Plant and Distribution System for Ships A.C. Generators

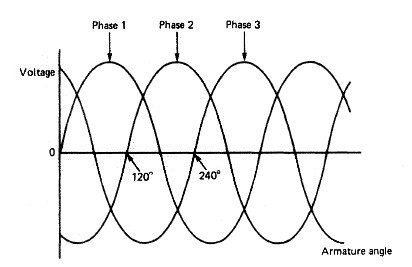

Alternating current is a form of electricity in which the current

alternates in direction (and the voltage alternates in polarity) at a frequency defined by

the generator (usually between 50 and 60 times per second, i.e., 50 – 60 hertz). AC was

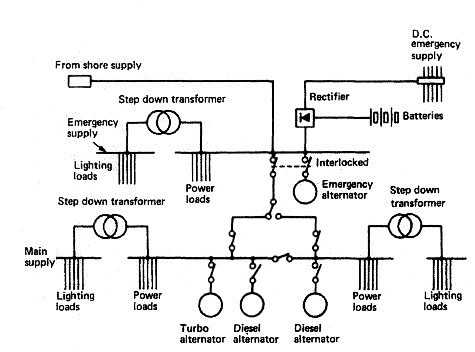

adopted for power transmission in the early days of electricity supply because it had

two major advantages over direct current (DC): its voltage could be stepped up or down

according to need using transformers, and it could be interrupted more easily than DC.

Neither advantage is as relevant today as it once was because power electronics can

solve both issues for DC.