Domestic Water System Merchant Ships

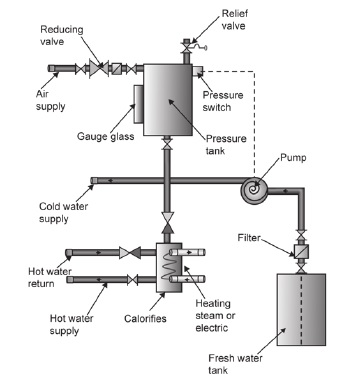

Domestic water systems usually comprise a fresh water system for

washing and drinking and a salt water system for sanitary purposes

. Both use a basically similar arrangement of an automatic

pump supplying the liquid to a tank which is pressurised by compressed

air.

The compressed air provides the head or pressure to supply the water when required. The pump is started automatically by a pressure switch which operates as the water level falls to a predetermined level. The fresh water system has, in addition, a calorifier or heater which is heated, usually with steam.

The compressed air provides the head or pressure to supply the water when required. The pump is started automatically by a pressure switch which operates as the water level falls to a predetermined level. The fresh water system has, in addition, a calorifier or heater which is heated, usually with steam.