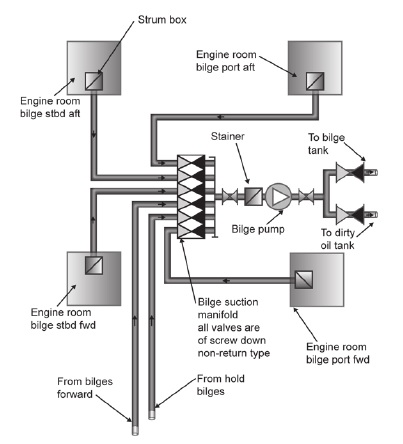

Sketches and Diagrams of Bilge and Ballast Systems for Marine Machinery Spaces

The function of the bilge system is to be capable of pumping from

and draining any watertight compartment within the ship, except

for ballast, oil and water tanks. The capacity or size of pumps in

the system depend on the size, type and service of the ship.

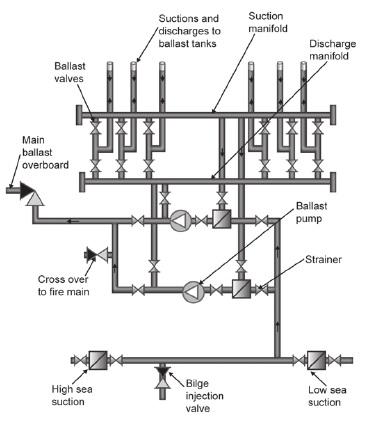

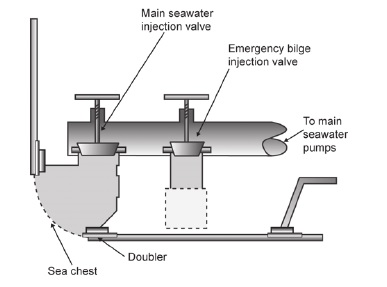

The function of the ballast system is to pump to and empty all spaces in the ship in which ballast water can be supplied. The suction pipes for the ballast system will be completely separated from the bilge system. The ballast system can also be used for other purposes in emergencies, such as supplying water to the fire main.

The function of the ballast system is to pump to and empty all spaces in the ship in which ballast water can be supplied. The suction pipes for the ballast system will be completely separated from the bilge system. The ballast system can also be used for other purposes in emergencies, such as supplying water to the fire main.