Boiler Mountings - Safety Valves, Mam Steftm Stop Valve & Auxiliary Steam Stop Valve

Marine boiler is an apparatus used to produce steam, either for a ships main propulsion or for auxiliary

machinery. A boiler is, in general, any closed liquid-containing vessel to which heat is

applied. It is also called steam generator as it transforms water into steam. Boilers

generally consist of metal shells (or bodies), headers and tubes that form the container of

the steam and water under pressure and, in certain types, of the furnace and passages for

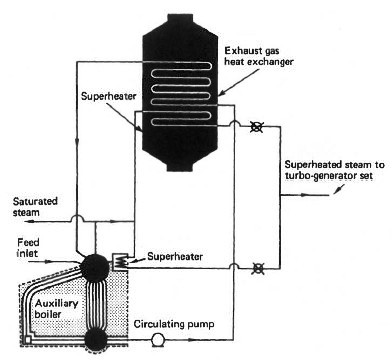

the hot gases. Some boilers have additional drums called superheaters.