Advantages of various Heat exchangers - Shell / tube and plate type

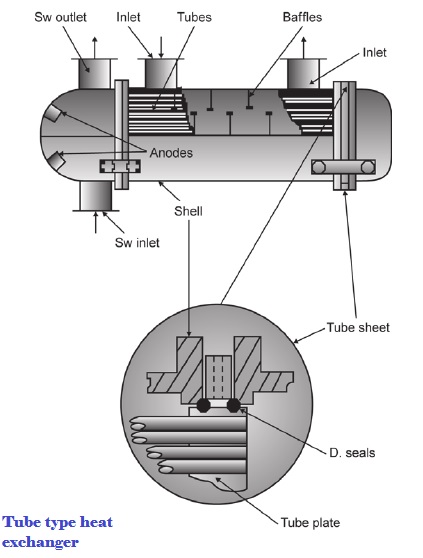

Sketch of a shell type heat exchanger:

The sketch shows a tube/shell type cooler that could be used as

a main engine jacket water cooler. The cooler shown is of the

two pass type, the jacket water being cooled, coming in contact

with the outer side of the tube stack, and the shell surface.

Baffles are used to direct the flow of jacket water through the

cooler, and also support the tube stack.

Seawater, being the cooling medium, is in contact with inside of

the tubes.