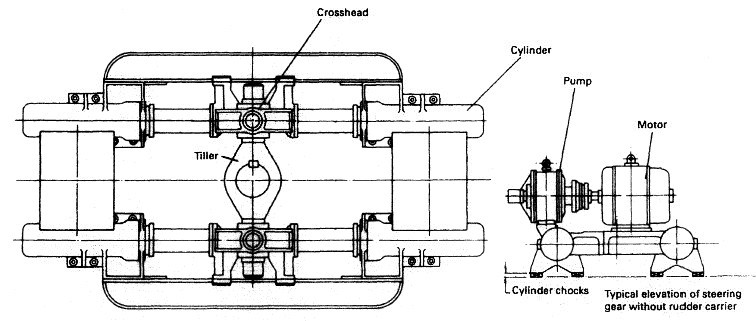

Ships Steering Gear Arrangement & Testing

Steering Gear – is used for of steering the ship. It is in constant use when the ship

is underway, and any failure or malfunction may result in disaster. The steering system

usually consists of: a steering gear, a control equipment, a rudder carrier, a rudder

and a rudder horn. The steering gear provides a movement of the rudder in response to

a signal from the bridge. The control equipment conveys a signal of ordered rudder angle

from the bridge and activates the steering gear to move the rudder to the desired angle.