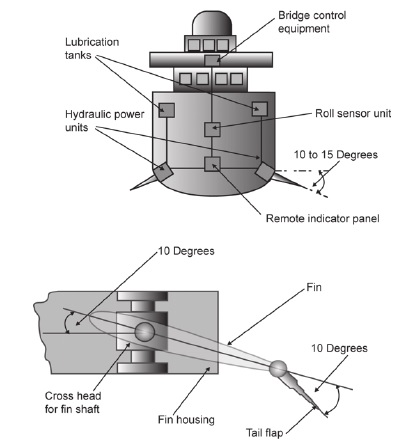

Fin Stabilisers for Controlling Ships Motion

Stabilising fins are fitted to ship's sides below the waterline to

reduce rolling of the hull by wave action.

The fins achieve this by imposing an equal and opposite

motion. Retractable fins of aerofoil section use the forward

velocity of the ship to create this opposing motion. As

the ship rolls to starboard, the starboard fin is set by a

gyroscope signal so that the leading edge of the fin is set

above the axis of tilt, giving an upward thrust. The port fin is

set in the opposite tilt, with its leading edge below the axis of

tilt, giving a downward thrust, and vice versa when the ship

rolls to port.