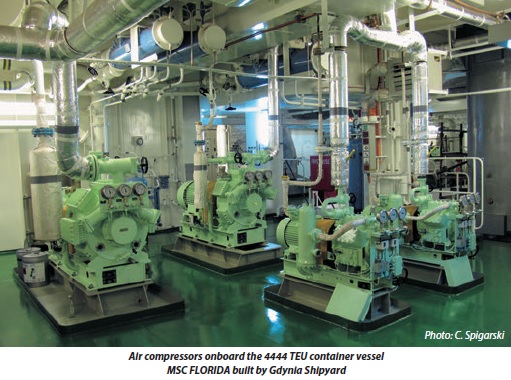

Compressed Air Systems for Various Shipboard Operations

The main aim of a compressor, as the name suggests, is to compress air or any fluid in order to reduce its volume.

Some of the main applications of compressors onboard ships are main air compressor, deck air compressor, AC compressor and refrigeration compressor.

Failure to start or control air compressor can be inconvenient, costly and can carry risks, which need to be managed.