Inert gas system for machinery installations onboard

Inert gases are those which do not support combustion and are largely

nitrogen and carbon dioxide. Large quantities suitable for fire

extinguishing can be obtained by burning fuel in carefully measured

amounts or by cleaning the exhaust gases from a boiler.

Inert gas generator

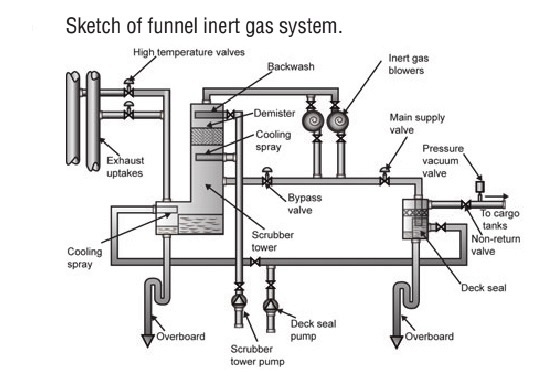

The inert gas generator (Figure below) burns fuel in designed quantities to produce perfect combustion. This provides an exhaust gas which is largely nitrogen and carbon dioxide with a very small oxygen content.

The exhaust gases pass to a cooling and washing chamber to remove sulphur and excess carbon. The washed or scrubbed exhaust gas is now inert and passes to a distribution system for fire extinguishing.

Inert gas generator

The inert gas generator (Figure below) burns fuel in designed quantities to produce perfect combustion. This provides an exhaust gas which is largely nitrogen and carbon dioxide with a very small oxygen content.

The exhaust gases pass to a cooling and washing chamber to remove sulphur and excess carbon. The washed or scrubbed exhaust gas is now inert and passes to a distribution system for fire extinguishing.