Home || Diesel Engines

||Boilers||Feed Systems

||Steam Turbines ||Fuel Treatment ||Pumps ||Refrigeration ||

Detection of piston overheating in a marine diesel engine

Piston forms the lower part of the combustion chamber in a marine diesel engine. It seals the cylinder and transmits the gas pressure to the connecting rod.

The piston absorbs heat of combustion and this heat must be conducted away if the metal temperature is to kept in safe limits.

Below are the most common reasons of Piston running hot :

i) Inadequate circulation of cooling media and or supply not sufficient

ii) Excessive deposit in cooling space (scale or carbon)

iii) Lubrication not sufficient

iv) Faulty piston ring : clearance inadequate. Too high temperature top ring groove area – blow by.

v) Distorted cylinder liner

vi) Misalignment of piston

vii) Overloading of unit – excessive fuel

viii) Excessive water content in fuel

ix) Insufficient air from turbocharger or manifold

x) Late injection of fuel – timing or fault injectors

xi) Engine running slow speed – full flow of coolant not maintained

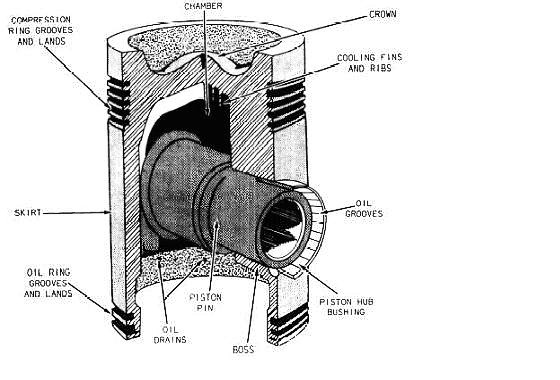

Fig:piston-configuration

Overheating is most likely to occur at slow speed as the cooling medium is not being agitated and its effectiveness is reduced. Below are the guideline to detect overheating.

i) A rise in the cooling return temperature

ii) Noise in the cooling system due to vapour locks

iii) Crankcase mist detectors shown high concentration – trunk engine

iv) Dry patches and discolouration on piston or exhaust valve

v) Smoke and smell

Summarized below more guidance for marine diesel engine piston handling safety procedure:

- Construction of 4 stroke piston

For medium and high speed engines the weight of the material becomes important to reduce the stresses on the rotating parts. The high thermal conductivity of aluminium alloys allied to its low weight makes this an ideal material. To keep thermal stresses to a reasonable level cooling pipes may be cast into prevent distortion.

More.....

- Piston oil cooling method - basic principle

The coolant used for removing and conveying the heat from a piston may be either fresh water, distilled water or lubricating oil. Water has the ability to remove more heat than lubricating oil ( specific heat of water approximately 4 and lubricating oil 2 and temperature difference 14 deg C for water and 10 deg C for lube oil)

.

More .....

-

Function of piston ring in a marine diesel engine

The efficiency of the engine depends upon the effective sealing between the piston and liners. Leakage will reduced compression pressure and power will lost. Piston rings seal the gas space by expanding outwards due to the gas pressure acting behind them. They also spread the lubricating oil up and down the cylinder liner and transfer heat to the liner walls Three to six power or compression rings are fitted to the piston, the number depending on weather the engine operates on the 2-stroke or 4-stroke cycle.

More .....

-

Requirement of piston ring

Piston forms the lower part of the combustion chamber in a marine diesel engine. It seals the cylinder and transmits the gas pressure to the connecting rod.

More .....

-

Piston designing considerations

Piston forms the lower part of the combustion chamber in a marine diesel engine. It seals the cylinder and transmits the gas pressure to the connecting rod.

More .....

Troubles of piston to be avoided

i) Piston seizure; all too often followed by an explosion of the lubricating oil – air mixture in the crankcase.

ii) Cracking of piston crown and side walls, due to cyclic variation of pressure stress superimposed on stress due to temperature gradient.

More .....

-

Detection of piston overheating

most common reasons of Piston running hot :

i) Inadequate circulation of cooling media and or supply not sufficient.

ii) Excessive deposit in cooling space (scale or carbon).

iii) Lubrication not sufficient.

More .....

Machinery Spaces.com is about working principles, construction and operation of all the machinery

items in a ship intended primarily for engineers working on board and those who working ashore . For any remarks please

Contact us

Copyright © 2010-2016 Machinery Spaces.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||